How HandPans are Made at panstream

The art of HandPan Making

HandPans are more than musical instruments – they are the result of patience, precision, and a deep respect for sound. Every handpan is shaped by human hands, careful listening, and countless small decisions that influence its final voice. At PanStream, we believe that understanding the making process helps players connect more deeply with their instrument.

In this post, we take you through the key stages of HandPan making, from raw steel to a fully tuned, expressive instrument.

Selecting the Steel

The journey of a handpan begins with steel. The type, thickness, and treatment of the steel all play a crucial role in how the instrument will sound and feel. High-quality steel provides stability, sustain, and responsiveness, allowing the notes to sing clearly while remaining structurally strong.

Choosing the right material is the foundation of everything that follows – a handpan can only be as good as the steel it is made from.

Most HandPans are made from either nitrided steel (known for its rust resistance) or stainless steel (favoured for its long sustain and warm tone). Each material affects the sound and feel of the final instrument.

Shaping the Shells

The next step is forming two hemispherical shells. These are usually created by deep-drawing or hydroforming flat steel sheets into dome shapes. The top shell will hold the notes; the bottom shell becomes the resonant chamber.

PanStream orders pre-made shells from Ayasa – Nitrided and Ember Steel.

Layout and Note Design

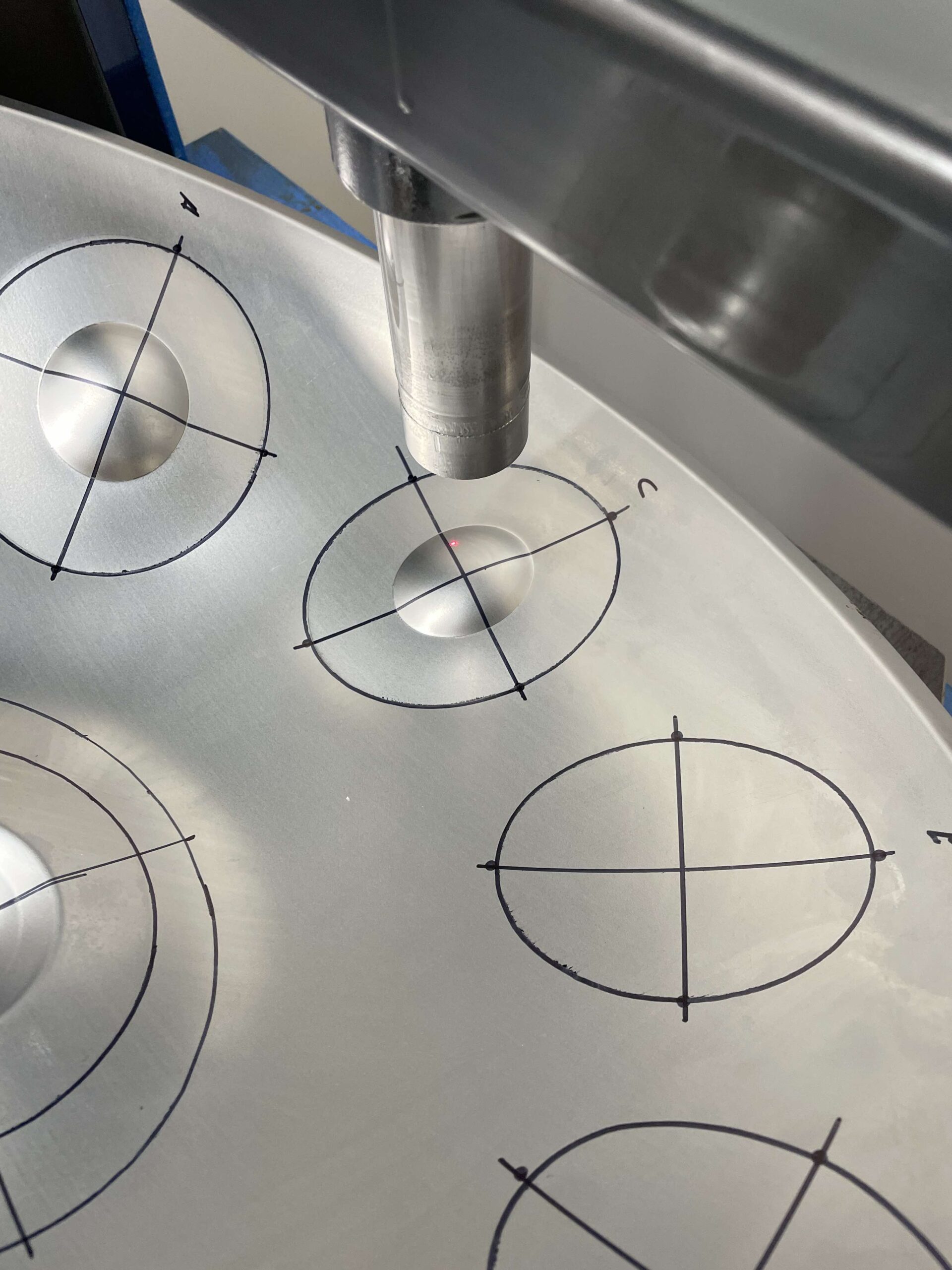

Once the top shell is shaped, the maker carefully marks out the note layout. This includes the central note (Ding) and the surrounding tone fields that will form the chosen scale. The spacing, angles, and overall geometry are thoughtfully designed to create a balanced, ergonomic, and intuitive playing experience.

Each marked area becomes what is known as a tone field. These tone fields are not yet sounding notes, but carefully planned zones where the steel will later be shaped and tuned. The position and size of each one directly influence pitch stability, overtone structure, and how comfortably the instrument responds to touch.

At this stage, the handpan exists only as potential. The notes are mapped with precision, but the sound itself has yet to emerge – waiting to be revealed through hammering and tuning.

Hammering (shaping) the Notes

Hammering is where the handpan truly begins to come alive. Using a combination of different hammers and techniques, the maker shapes each note field by hand. This process stretches and compresses the steel, defining the pitch and harmonic structure of each note.

There are two main approaches to shaping the steel at this stage:

Hand-hammering: This is the traditional, artisanal method where the maker uses a mallet to strike each tone field by hand. It requires thousands of controlled strikes, a deep understanding of how steel behaves under pressure, and a keen ear. Many players find that hand-hammered instruments have a warmer, more organic feel and richer overtones because each strike can be subtly varied by the maker’s touch.

Air-hammering: Also known as pneumatic hammering, this method uses a mechanical tool to deliver rapid, consistent strikes. It’s particularly useful for rough-forming shells and shaping large areas with high precision and speed, and can help achieve consistent shapes across multiple instruments. When combined with detailed hand finishing and tuning, air-hammered instruments can also produce beautiful, expressive tones.

You can read more about the differences between hand-hammered and air-hammered handpans in our in-depth post here: https://panstream.co.uk/hand-hammered-vs-air-hammered-handpans/

Every strike matters. Whether it’s done purely by hand or with pneumatic assistance, hammering still requires focus, consistency, and a trained ear, as the maker constantly listens to how the steel responds.

Tuning, Heat Treatment, and Stabilisation

Tuning a handpan is a delicate and time-consuming process that requires both technical precision and a highly trained ear. Each note must be tuned not only to its fundamental pitch, but also to its harmonics – typically the octave and the fifth. Achieving the right balance between these elements is what gives a handpan its characteristic warmth, clarity, and sustain.

Tuning is never completed in a single pass. The maker repeatedly tunes, listens, adjusts, and retests each note until the instrument feels stable, balanced, and musical across its entire range. Subtle changes to one note can affect others, making this stage highly interconnected and intentionally slow.

To help the instrument maintain its tuning over time, the shell undergoes a heat-treatment process. This hardens the steel and stabilises the internal stresses created during shaping and tuning. After heat treatment, the HandPan is tuned again by hand – sometimes multiple times – to refine the fundamental tone, octave, and fifth harmonic of each note.

This stage demands great patience and experience. Tuning and stabilisation are both a science and an art, guided by careful measurement but ultimately shaped by deep listening and feel.

Gluing the Halves

Once both shells are fully prepared, they are carefully joined together. The alignment of the shells, the seal, and the finishing all affect the instrument’s resonance and projection.

The Gu on the bottom shell is refined to ensure proper airflow and a deep, controlled bass response.

Final Tuning and Playing test

After the glue has cured, the instrument goes through a final tuning session and playing testing. This is where the maker checks balance, dynamic range, and overall musicality.

Only when the instrument feels coherent, expressive, and inspiring is it considered complete.

The HandPan is then cleaned and polished, and coated with a protective layer. Then we do a final sound test before the instrument leaves the workshop.

A Note on Handmade Instruments

Unlike mass-produced instruments, every handpan carries subtle differences that make it unique. The process is slow by design, guided by listening rather than machines. This human touch is what gives each handpan its character and soul.

Each HandPan is a one-of-a-kind creation. Subtle variations in hammering, material, and tuning contribute to the character of each instrument; no two are exactly alike.

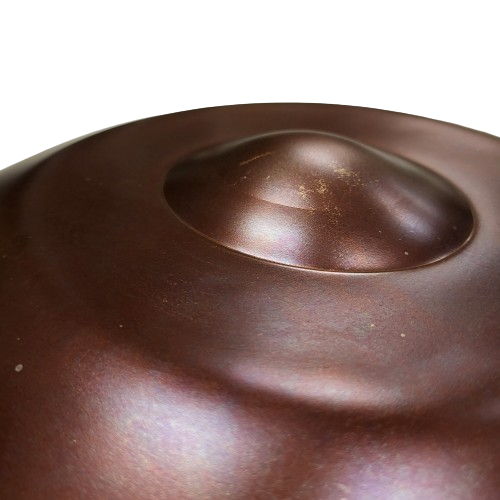

During the heat-treatment process, each piece also develops its own distinct colouration, shaped by the temperature and time in the oven. Because of this, specific colours can’t be guaranteed – every HandPan is naturally unique.

At PanStream, we embrace this process with care and respect, creating instruments that are meant to be played, explored, and loved for years to come. Buying directly from a maker ensures not just quality, but also a more personal connection to the instrument you’re playing.

Want to Know More?

Curious about the process, or thinking of ordering a custom build?

Contact us – we’re always happy to chat about the craft of HandPan making.