How HandPans are Made

The Craft Behind the Sound

HandPans are more than musical instruments – they are resonant sculptures, shaped with care, precision, and a deep understanding of acoustics. At PanStream, every instrument is handcrafted by Mark Wilson in our Devon, UK-based workshop. Here’s a short look at how these unique instruments come to life.

Choosing the Steel

It all starts with high-quality steel. Most HandPans are made from either nitrided steel (known for its rust resistance) or stainless steel (favoured for its long sustain and warm tone). Each material affects the sound and feel of the final instrument.

PanStream mostly works with Stainless Steel

Forming the Shells

The next step is forming two hemispherical shells. These are usually created by deep-drawing or hydroforming flat steel sheets into dome shapes. The top shell will hold the notes; the bottom shell becomes the resonant chamber.

PanStream orders pre-made shells from Ayasa – Ember Steel

Shaping the Notes

On the top shell, each note area is carefully marked and shaped, creating what’s called a tone field. This involves precision hammering, by hand or with mechanical tools, to define the pitch, overtones, and responsiveness of each note.

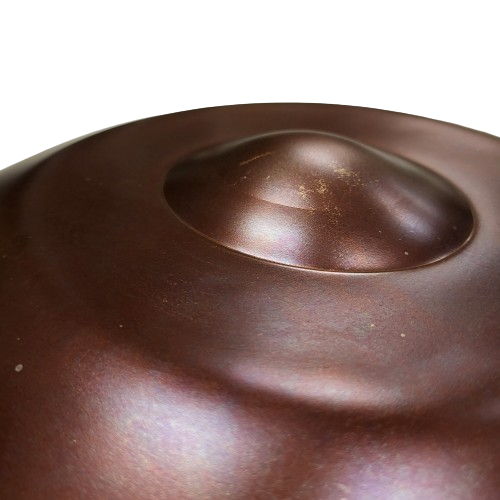

The central note (or ding) sits in the middle, surrounded by a circle of tuned tone fields.

Heat Treatment and Tuning

The shell is then heat-treated to harden the metal and improve tuning stability.

After this, the instrument is tuned by hand, sometimes multiple times. The tuner listens closely and gently hammers the steel to refine the note’s fundamental tone, octave, and fifth harmonic.

This stage requires great skill and patience – tuning is both a science and an art.

Gluing the Halves

Once tuning is complete, the top and bottom shells are glued together to form a sealed, resonant chamber. The bottom shell usually has a port or hole called “Gu“, which helps with projection and airflow.

Final Tuning and Finishing

After the glue has cured, the instrument goes through a final tuning session.

The HandPan is then cleaned and polished, and coated with a protective layer. Then we do a final sound test before the instrument leaves the workshop.

A Note on Handmade Instruments

Each handpan is a one-of-a-kind creation. Subtle variations in hammering, material, and tuning contribute to the character of each instrument, no two are exactly alike.

During the heat-treatment process, each piece also develops its own distinct coloration, shaped by the temperature and time in the oven. Because of this, specific colours can’t be guaranteed – every HandPan is naturally unique.

Buying directly from a maker ensures not just quality, but also a more personal connection to the instrument you’re playing.

Want to Know More?

Curious about the process, or thinking of ordering a custom build?

Contact us – we’re always happy to chat about the craft of HandPan making.